Advances Enable Speed Gains in Organizing and Analyzing Nanomanufacturing Data

Outcome/Accomplishment

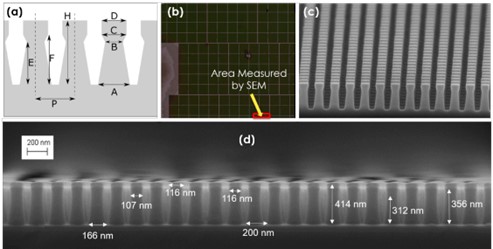

Advanced tools for organizing and mining big sensor and metrology data in nanomanufacturing were developed using first-principle based physics and Machine Learning (ML) concepts at the Nanomanufacturing Systems Center (NASCENT), an NSF-funded Engineering Research Center (ERC) based at the University of Texas at Austin.

Impact/Benefits

The advanced database technologies will enable fast-inspection techniques for real-time defect detection, characterization, and analysis of nanomanufacturing processes. The new approaches to data manipulation will help enable the real-time feedback and fault diagnostics needed for scaled-up production of tiny metal components.

Explanation/Background

Location

Austin, Texaswebsite

Start Year

Advanced Manufacturing

Advanced Manufacturing

Lead Institution

Core Partners

Fact Sheet

Outcome/Accomplishment

Advanced tools for organizing and mining big sensor and metrology data in nanomanufacturing were developed using first-principle based physics and Machine Learning (ML) concepts at the Nanomanufacturing Systems Center (NASCENT), an NSF-funded Engineering Research Center (ERC) based at the University of Texas at Austin.

Location

Austin, Texaswebsite

Start Year

Advanced Manufacturing

Advanced Manufacturing

Lead Institution

Core Partners

Fact Sheet

Impact/benefits

The advanced database technologies will enable fast-inspection techniques for real-time defect detection, characterization, and analysis of nanomanufacturing processes. The new approaches to data manipulation will help enable the real-time feedback and fault diagnostics needed for scaled-up production of tiny metal components.